SEAMLESS PLASTIC TUBES

Believed to be the most ideal packaging solution for the cosmetic industry, due to its high aesthetic value and easy adaptability to numerous decorative forms, the seamless plastic tube business is an exciting horizon for the packaging industry. Through constant innovation, Essel has successfully been manufacturing and delivering plastic tubes to new and emerging sectors. Our acquisition of Arista Tubes, a leading manufacturer of plastic tubes in the United Kingdom, has helped us absorb comprehensive and cutting-edge knowledge and experience in the sector.

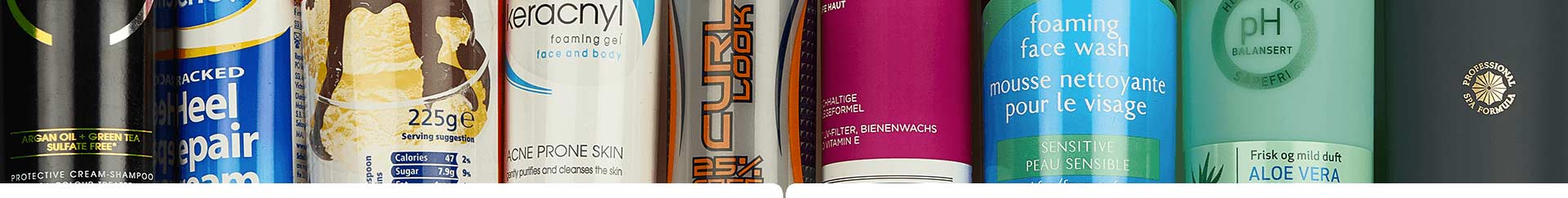

Seamless plastic tubes are used to package high-end, low-volume products in a range of industries. They offer enhanced shelf life for goods and help create a unique product identity. Extruded tubes offer an attractive and durable packaging solution for a variety of product lines. From custom coloured materials to high-end decoration techniques, Essel offers solutions that can be customized to any kind of product or market.

Structures Offered:

- Monolayer options include LLDPE, LDPE, MDPE and HDPE.

- Multilayer options include co-extruded 2 layer sleeve, co-extruded 5 layer LLDPE sleeve with monolayer shoulder and co-extruded 5 layer HDPE sleeve with monolayer shoulder.

Decorations can be made available in up to 8 colours offset (line & text, vignettes and illustrations), up to 6 colours silkscreen and metallic & pearlescent inks.

Hot stamping

Labeling options include full wrap, front & back, label sets and patch labels, as well as multi-layer and tactile labels. Extruded tubes are manufactured, printed and capped in-line. Special decorations such as silk screen printing, foil blocking and labeling are secondary processes.

PLASTIC TUBE PROCESS

Co-Extrusion (Sleeving)

Essel is equipped with sophisticated facilities that manufacture co-extruded sleeves. Our machines have high flexibility to process a huge variety of colours and specifications. A complete tube extrusion line involves a number of other machines, such as a header, print / lacquering, capping, decoration and packaging machines.

Co-extrusion ensures automatic diameter control allowing laser measurement to be taken with digital display. This guides the operator to make prompt and precise changes in setting the tube diameter. The process has become an essential tool in guaranteeing quality. Tube sleeves that lie outside the specified tolerance range are rejected automatically. Essel manufactures a wide spectrum of co-extruded sleeves ranging from the typical 19mm to 60mm, up to 560 microns and also a length ranging from 80mm to 210mm.

Dry Offset Printing

Essel has facilities for offset printing, also referred to as offset lithography. In this process the ink is not directly pressed onto the paper, but is distributed from a metal plate to a rubber mat where it is then set onto the paper. The colours used in offset printing are usually Cyan, Magenta, Yellow and Black, represented with the letters CMYK. Different percentages of each of these four colours create virtually every colour used in offset printing. There are colour matching systems, such as the PANTONE® system, that allows print buyers to see the colour. The code for that colour can be entered into the offset printer’s computer and it will calculate the percentages of each colour to be used.

Screen Printing

Essel has all the required contemporary art facilities for screen printing since it is the most preferred compared to other processes such as dye sublimation or inkjet printing because of its low cost and ability to print on many types of surfaces. Screen printing, silk screening or serigraphy is a printing technique that creates a sharp-edged image using a stencil. A screen print or serigraph is an image created using this technique. Screen printing is preferred due to the ability to print on diverse background substrates.

Hot Stamping (Foil Blocking)

The Hot Foil Stamping process is a thermal bonding technique that results in the permanent adhesion of stamping foil to the target surface. Essel has modern facilities for this highly ornamental and sophisticated process, whereby a metallic foil is applied to the printing substrate through a heated die (also referred to as ‘Foil Stamping’ or ‘Foil Blocking’). Hot Foil Stamping is a type of film that is widely used for creating a decorated sheet, which is then applied to plastic, wood, leather and paper. Hot stamping foil is available in a wide range of unique dimensions, colours and patterns.

Labeling

When complexity of design exceeds the parameters of ‘Offset’ and ‘Silk Screen Printing’, labeling is used as an alternative. Labeled tubes are also useful when producing small runs for test marketing or foreign language variants.